How can an automated washer-disinfector transform your hygiene/decontamination cycle?

Manual cleaning vs. an automated washer-disinfector

Manual cleaning and disinfection is time-consuming, not easily validated, and often the weakest link in the decontamination process. In standard operating procedures, manual steps need to be precisely described, and the disinfectants used clearly defined. Yet, deviations from these guidelines, which might go unnoticed or be deemed insignificant due to lack of awareness, are always possible. On the other hand, machine-based cleaning and disinfection in a washer-disinfector records and monitors the entire process. Any errors are promptly identified and documented in the protocol. On-site commissioning and regular revalidations meet the regulations, which demand a safe, traceable, and consistent decontamination pathway of instruments.

The more modern way

Fully automated processing represents the logical progression from previous methods. The "modern" decontamination pathway becomes more streamlined, organised, and time-efficient with the use of a washer-disinfector. This device replaces the need for an ultrasonic bath and sink for instrument rinsing. Instruments used are placed directly into the machine; pre-cleaning is usually unnecessary in podiatry. Processing through a washer-disinfector simplifies and saves a significant amount of time that can be redirected towards treatments or other essential practice tasks.

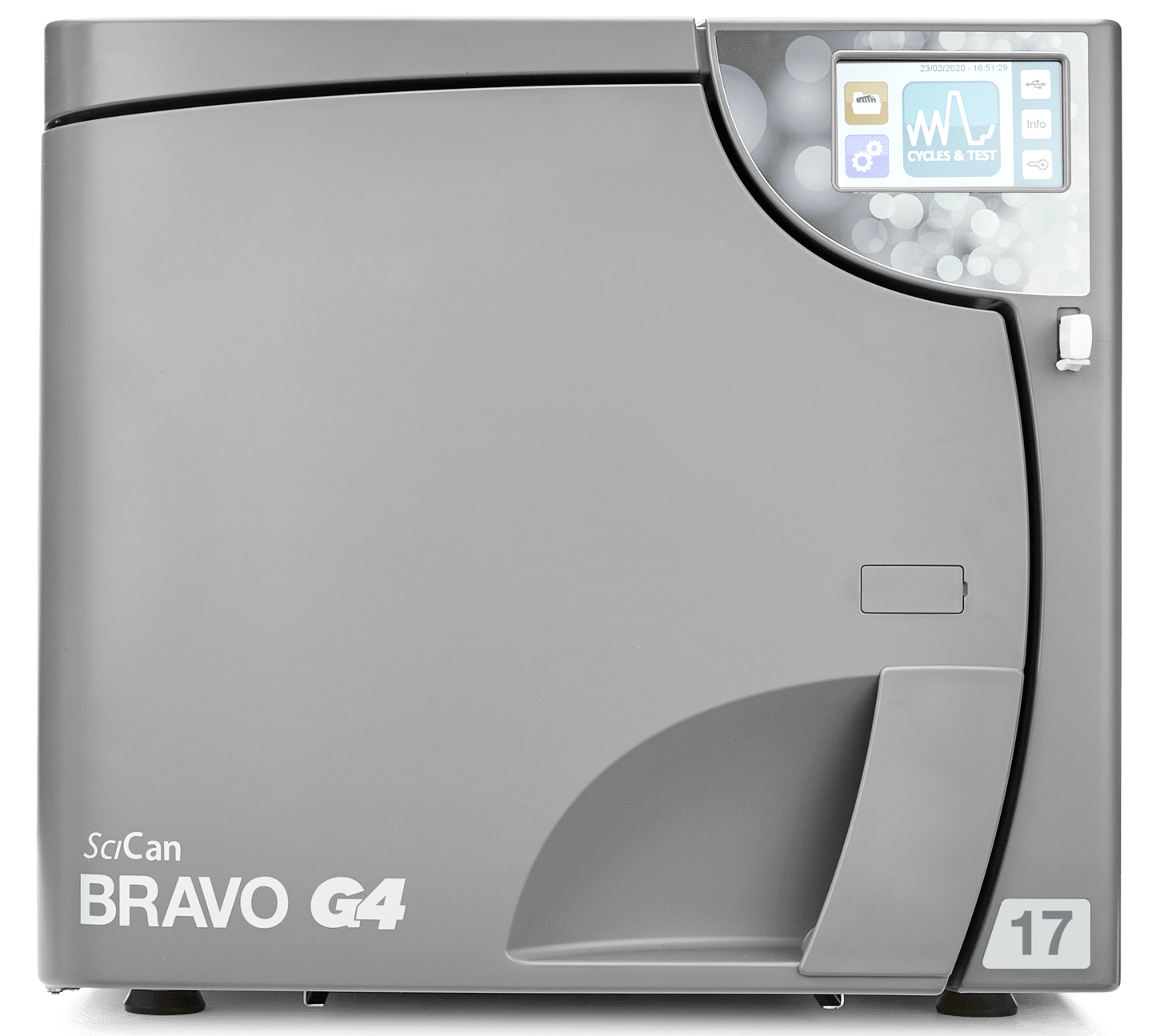

Now within reach

Due to the large size of the available units, automated instrument washer-disinfectors have traditionally been out of reach for the typical size of podiatry practice. Until now! Washer-disinfectors provide podiatry practices with a safer, more effective and more efficient way to clean and disinfect instruments. This is because they eliminate the labour-intensive and time-consuming steps of manual cleaning, rinsing and drying. They also help to create a safer work environment by minimising physical handling of contaminated instruments, which reduces the risk of sharps injuries, and preventing the creation of aerosols. Using a washer-disinfector is the Royal College of Podiatry preferred method for cleaning podiatry instruments. This is because every set of instruments receives the same validated cleaning and disinfection process with each cycle through dosing the correct and consistent amount of detergent. This allows instruments to immediately be transferred to the next step in the decontamination cycle: sterilisation.

We are happy to use our extensive knowledge to help and guide you further on the topic of decontamination. Feel free to chat to us online or e-mail us:

RUCK Advice & Design Service contact@hellmut-ruck.uk