Autoclaves

Would you like to be part of the next chapter in our story?

We provide inspiring stories, top tips and informative discussion topics within the area that interests you most: podiatry and all things feet! Subscribe our newsletter & get free delivery!

Subscribe now

Sterilisation device for podiatry and chiropody

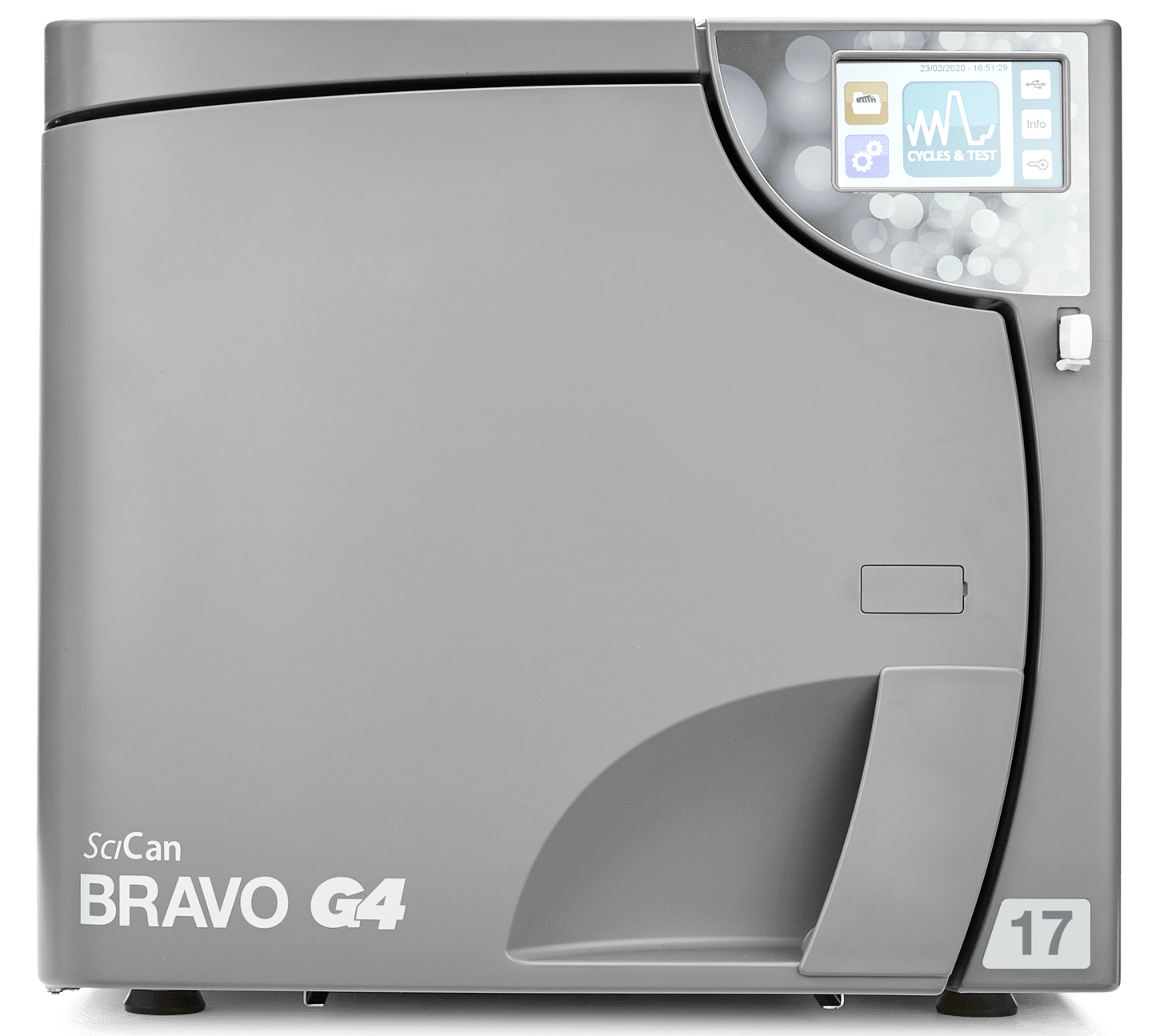

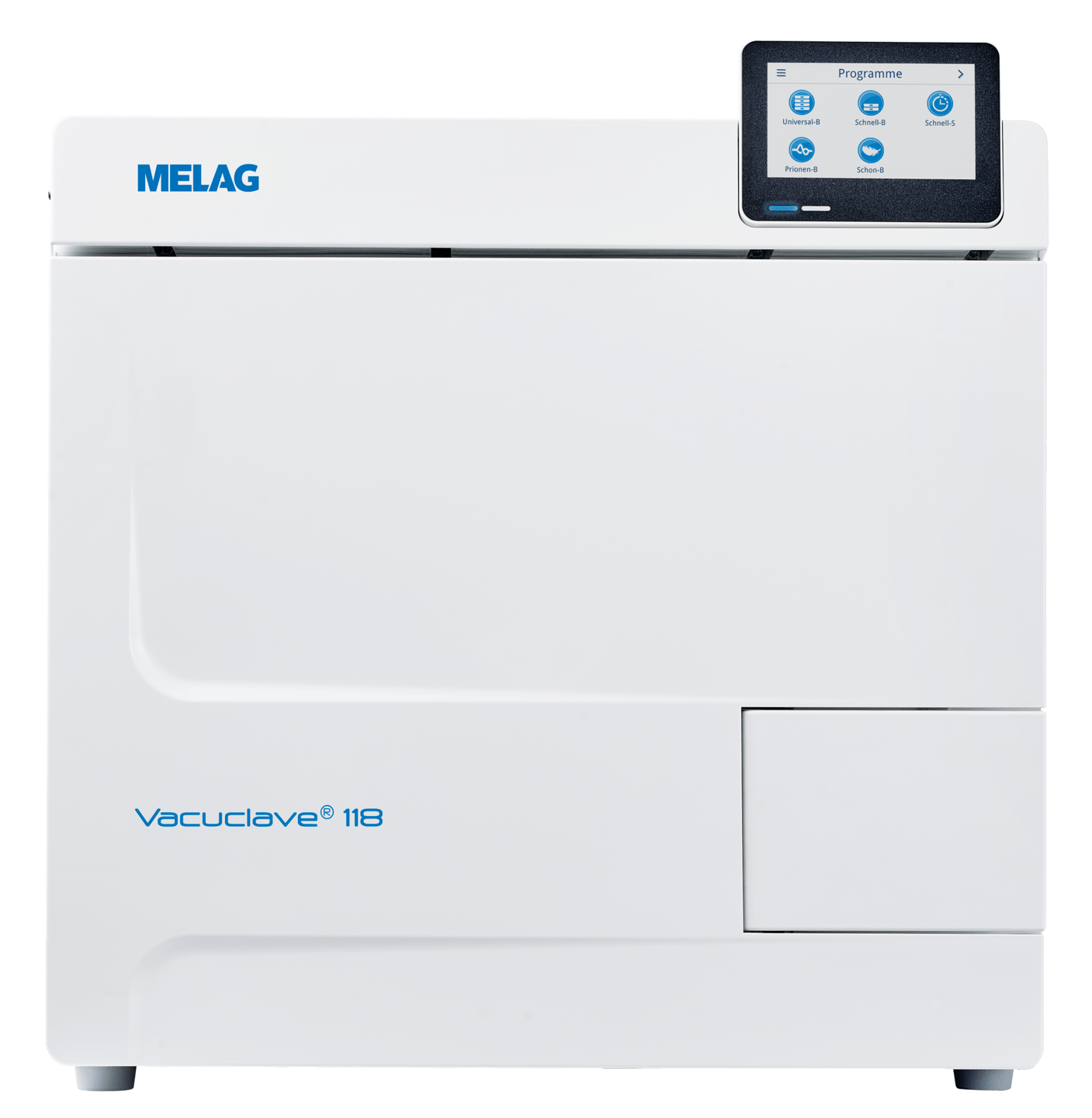

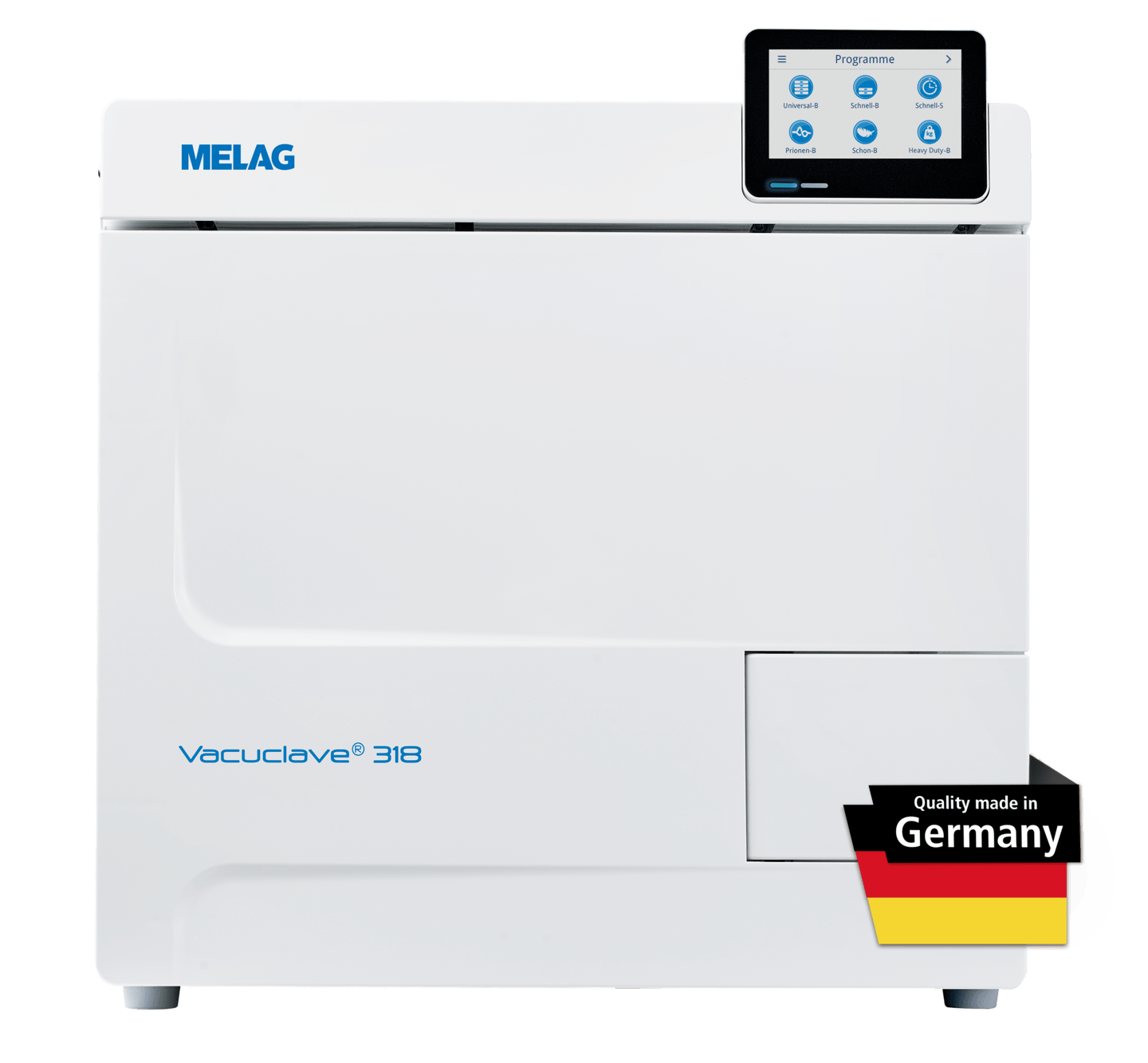

Sterilisation devices offer reliable sterility for instruments and equipment used in podiatry and chiropody. They minimise the risk of contamination and infection and ensure seamless hygiene in practice and mobile practice. Discover sterilisation devices from manufacturers such as Melag, Miele and SciCan now.

What does sterilisation mean?

Mechanical sterilisation is used to achieve absolute sterility thanks to the killing of all microorganisms. In this way, instruments can be cleaned in the hygiene cycle in accordance with legal requirements and stored antiseptically for application. Seamless documentation of sterilisation procedures is important.

How does sterilisation work in practice?

Mechanical sterilisation itself is usually carried out using autoclaves or hot air sterilisers, which ensure sterility thanks to heated steam in the case of autoclaves and very hot, dry air in the case of hot air sterilisers. Contaminated instruments and equipment are usually pre-cleaned beforehand using an ultrasonic cleaner or washer-disinfector. If instruments are to be kept sterile, then a film sealing device is also used to pack them airtight before sterilisation.

RUCK offers you these foot care professional sterilisers

In our product range, you can find the following types of sterilisation devices for the highest hygiene requirements:

- Autoclaves: an autoclave is also known as a steam steriliser and uses hot steam under high pressure to ensure absolute freedom from germs, viruses and spores. Steam pressure sterilisation can be used for medical, heat-resistant instruments and equipment, among other things. The hot steam in the autoclave reaches temperatures of up to 134 degrees and can be used to sterilise unwrapped instruments along with wrapped, sealed instruments. The drills differ in terms of chamber volume, size and capacity.

- Hot air sterilisers: In contrast to autoclaves, hot and dry air is contacted in hot air sterilisers instead of steam.

As slightly higher temperatures of up to 350 degrees can be reached here, germs and microorganisms are killed even more efficiently. While an autoclave requires several phases for sterilisation, from venting to pressure release, hot air sterilisation is a single process, which shortens the operating time.

Accessories for sterilisation devices and sterilisation steps

Comprehensive sterilisation requires accessories such as:

- Film sealers: these are used to seal in instruments that are to be sterilised and stored antiseptically.

- Ultrasonic cleaning devices or washer-disinfectors: Ultrasonic cleaners and washer-disinfectors (WDs) are used for quick, easy cleaning and disinfection. They are often required for the preparation and pre-cleaning of instruments to be sterilised.

- Water conditioners: To prevent contamination thanks to contaminated water, special water conditioners are required for autoclaves to ensure demineralisation and quality control.

- Documentation devices: An integral part of sterilisation is traceable process documentation, which is carried out via printer or app.

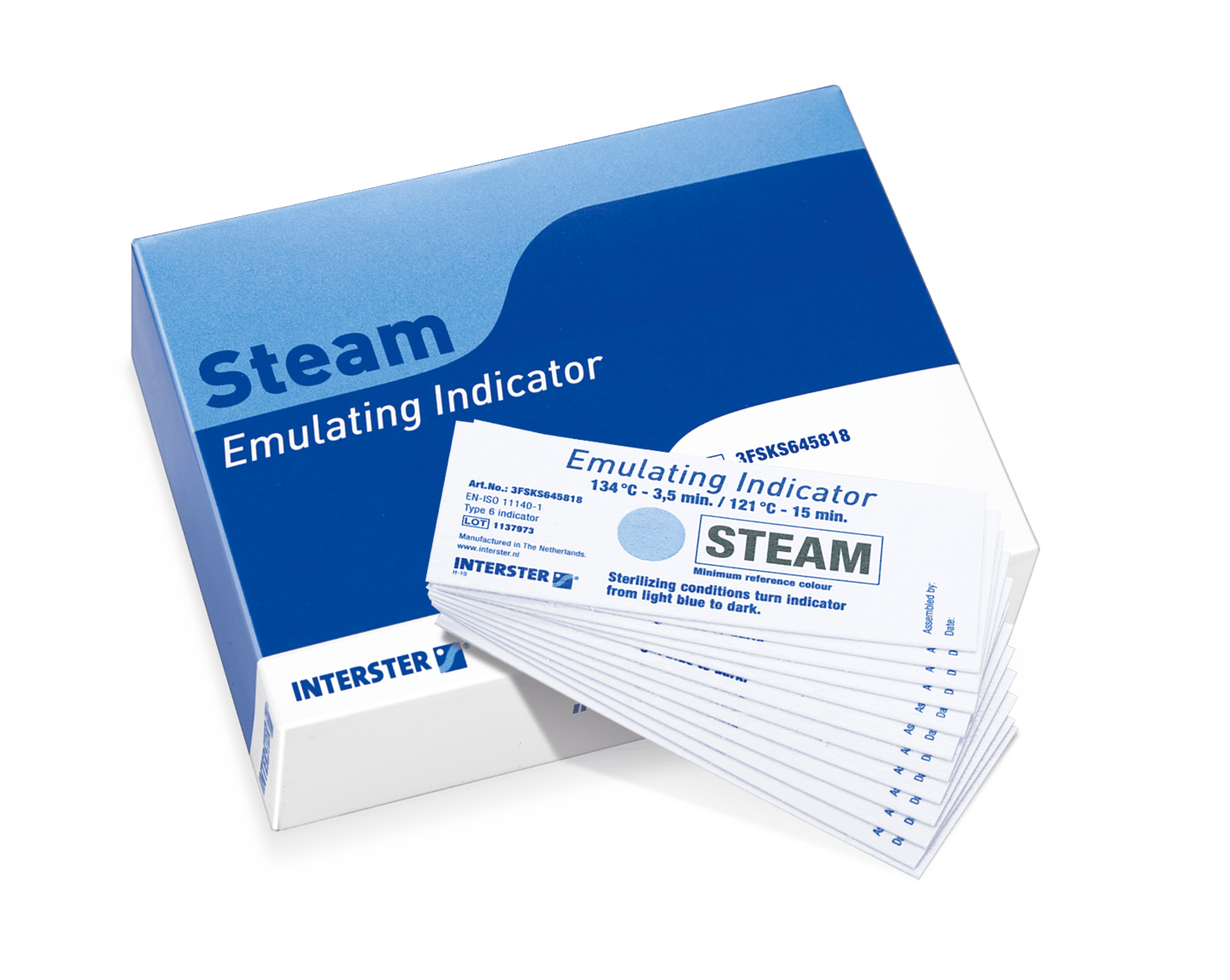

- Indicators and tests: Indicator systems and test strips are required to verify the accurate functioning of autoclaves and hot-air sterilisers along with correct sterilisation.

- Trays and uses: Trays, carriers and uses are used for the insertion or orderly insertion of attachments and instruments and for subsequent insertion into sterilisers. Carriers can also be welded together with instruments for sterile storage prior to sterilisation.

- Medical waste containers: Special medical waste containers are required for safe, low-contact disposal and emptying.

Buy sterilisation equipment for podiatry and chiropody at RUCK

With foot care professional sterilisers from renowned manufacturers such as Miele, Melag or SciCan, you can be confident of absolute sterility for instrument reprocessing in the hygiene cycle.